By Patrick Strauch, Executive Director of the Maine Forest Products Council

Printed by the Bangor Daily News

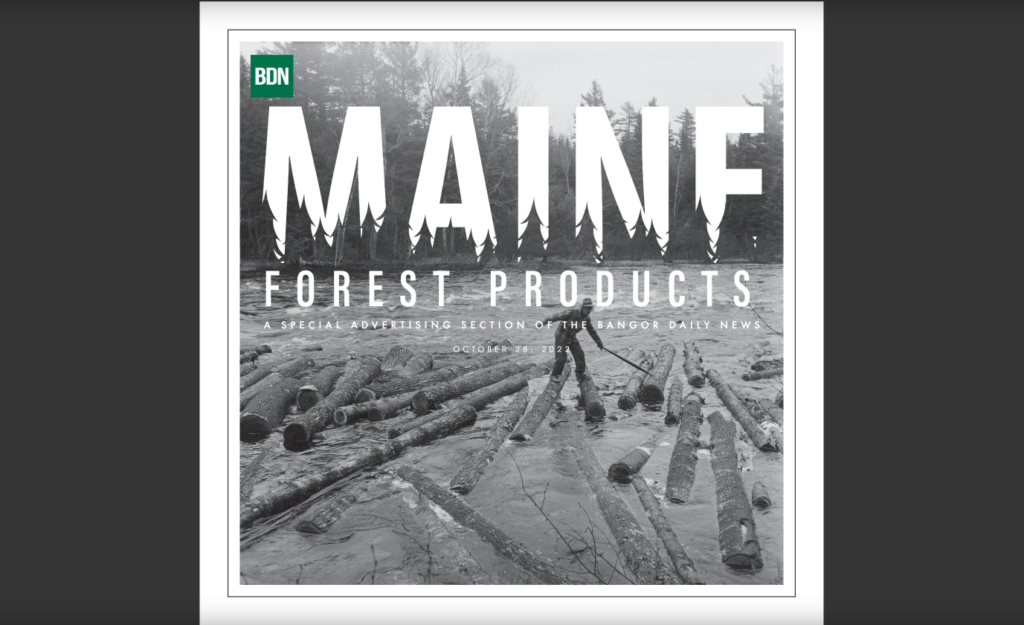

The forest products industry has been an integral part of Maine’s economy, culture and heritage for hundreds of years. While supporting an $8.1 billion industry, our sustainably managed working forests also provide unparalleled recreational opportunities, critical wildlife habitat, climate benefits, and clean water and air that make Maine a place like no other.

Each year, the forest products industry sustains 33,500 jobs, paying $1.8 billion in payroll and $278.4 million in state and local taxes. According to University of Maine research, one out of every 24 jobs in Maine is associated with the forest products industry, making it critical to our economy. These benefits are all possible thanks to diverse wood markets that support healthy forests and rural economies.

The forest products industry has been a cornerstone of economy since before Maine became the 23rd state in the Union. It is woven into the fabric of our past, and, thanks to investments and innovation, the Maine Forest Products Council is confident that our industry will continue to grow despite some transitional bumps in recent years.

Just recently, the Maine Forest Products Council joined our 2022 Outstanding Manufacturer of the year, LP Building Solutions, in celebrating the grand re-opening of their Houlton Facility. Thanks to a $150 million investment, the Houlton Facility is now the first location on the east coast producing LP SmartSide, an innovative and popular siding material that is in high demand. With this investment, the Houlton Facility will be secure for years to come.

There are countless examples of investments and innovation taking place now in the industry. Pleasant River Lumber has made several major improvements to modernize and expand. Robbins Lumber Company has also made significant investments in biomass and technology, allowing their company to stay on the cutting edge.

Timber HP is investing $85 million to transform the shuttered Madison Mill into a wood fiber manufacturing facility. Irving Sawmills in Dixfield recently invested $26.5 million in a state-of-the-art planer mill that will allow Irving to use scanning technology to capture more value in logs. Our paper mills are investing in new technologies to diversify their product lines and remain competitive in the global marketplace.

With innovation, led by the University of Maine’s Composites and bioproducts divisions, investments by industry leaders and an increased awareness of the need for renewable, sustainable and recyclable materials like wood, the future is bright for the forest products industry in Maine, but to harness the opportunities in front of us, the industry will need 5,000 additional employees by 2030.

We celebrated National Loggers Day on October 12. Established by a bipartisan group of US Senators including our very own senators, Susan Collins and Angus King, it recognized the challenges loggers face on the front lines of a turbulent economy. The immediate challenge Maine faces is replacing an aging workforce and bringing more people into the working economy. Maine’s forest industry is healthiest when all the sectors of forest economy (landowners, loggers and wood manufacturing and mills) are operating at full capacity. MFPC is working with other associations, government officials and policy leaders to achieve the vision of a growing forest economy.

For our industry, opportunities are abundant. With a little Yankee ingenuity, there is no problem we can’t solve.